APCO Engineering

Polar Operations, Specialised Equipment and Services

Anthony le Fevre

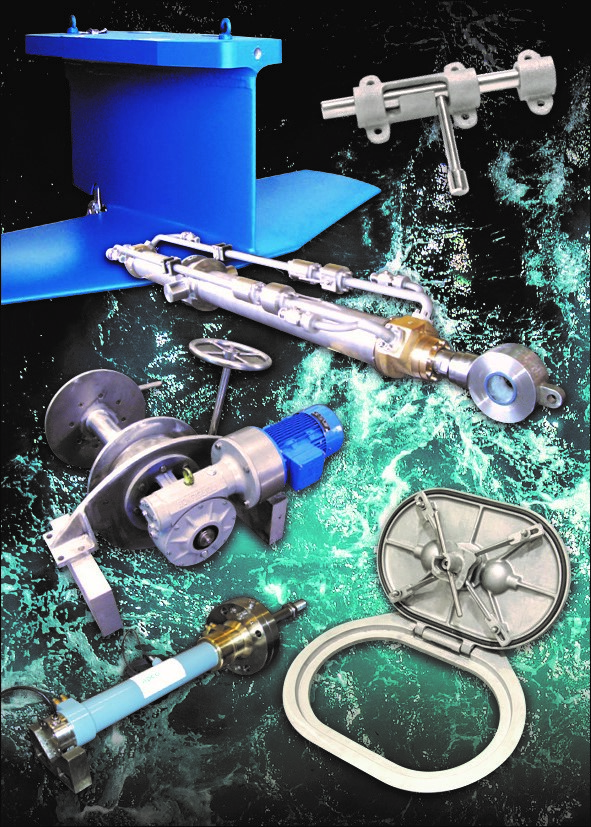

APCO Engineering produces high-quality cast and machined components and fittings in ferrous and non-ferrous metals. These include corrosion-resistant hydraulic actuators, aluminium deck hatches, bulkhead shaft seals, aluminium and stainless steel pipe fittings and custom-made parts to suit specific requirements, including polar operations.

The company has manufactured parts for the Australian Antarctic Division, the CSIRO Marine Laboratories and for the Australian marine research vessel Southern Surveyor and the French Antarctic vessel L’Astrolabe.

In-house foundry and machine shop facilities are backed up by years of experience. APCO can respond quickly to customer needs and produce parts to customer specifications.

The modern foundry is equipped with the latest technology, including a solid metal spectrometer, solidification simulation software and electric induction melting furnaces. This ensures total control of production processes and guarantees customers that APCO products have the highest casting and metal quality.

A modern machine shop incorporates both conventional and CNC machines, including the latest Mazak Integrex I-400S five axis Multi-Tasking Machine and FJV 60/120 Machining Centre. CNC machining is backed up with CAD/CAM technology ensuring accurate machining of the most challenging profiles.